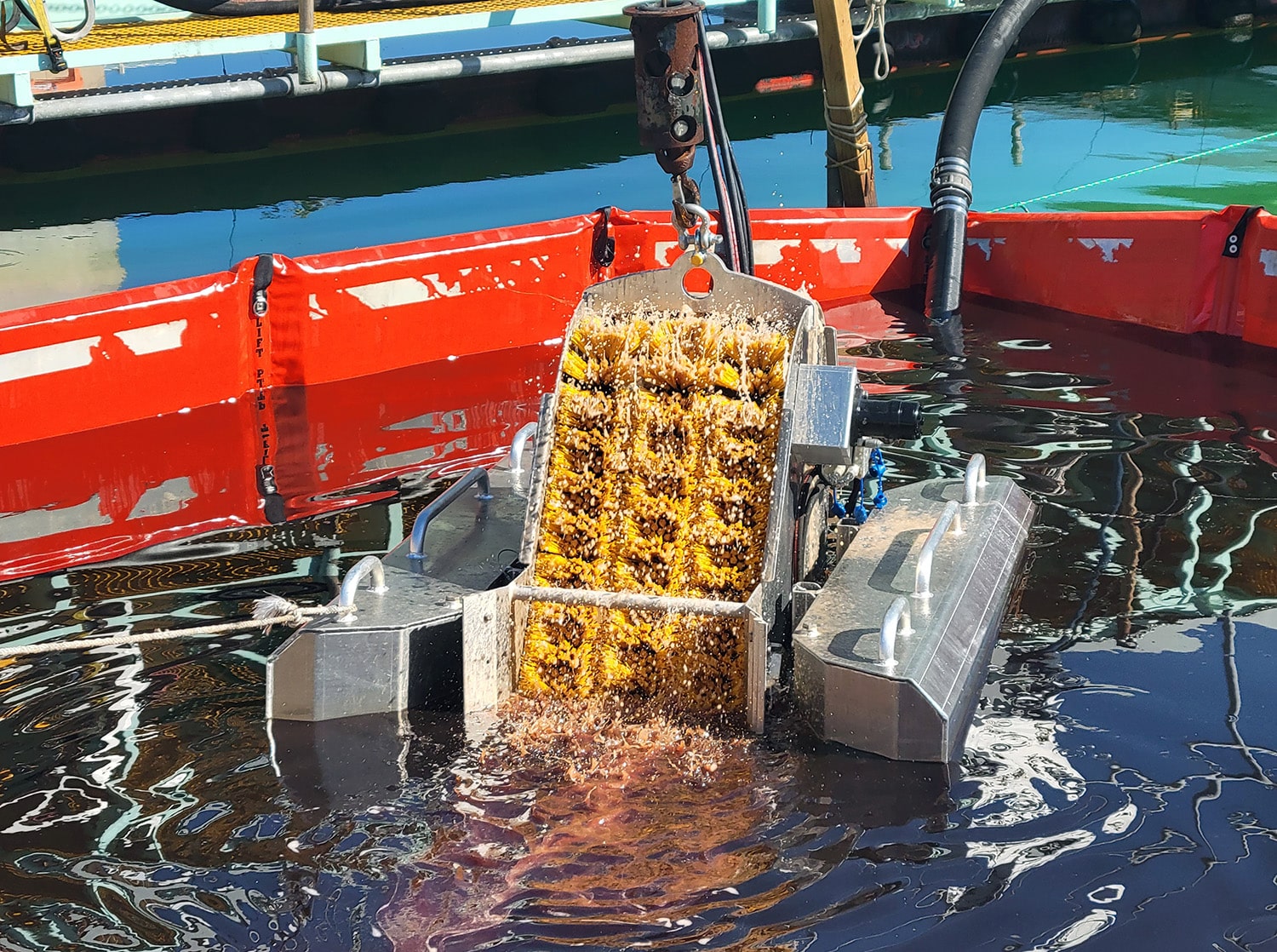

Ohmsett's unique testing venue plays an essential role in developing and evaluating cutting-edge technologies. Through testing and research, developers and manufacturers can meet the various Technology Readiness Level (TRL) gates necessary to move from a prototype to a full-scale commercialized product.

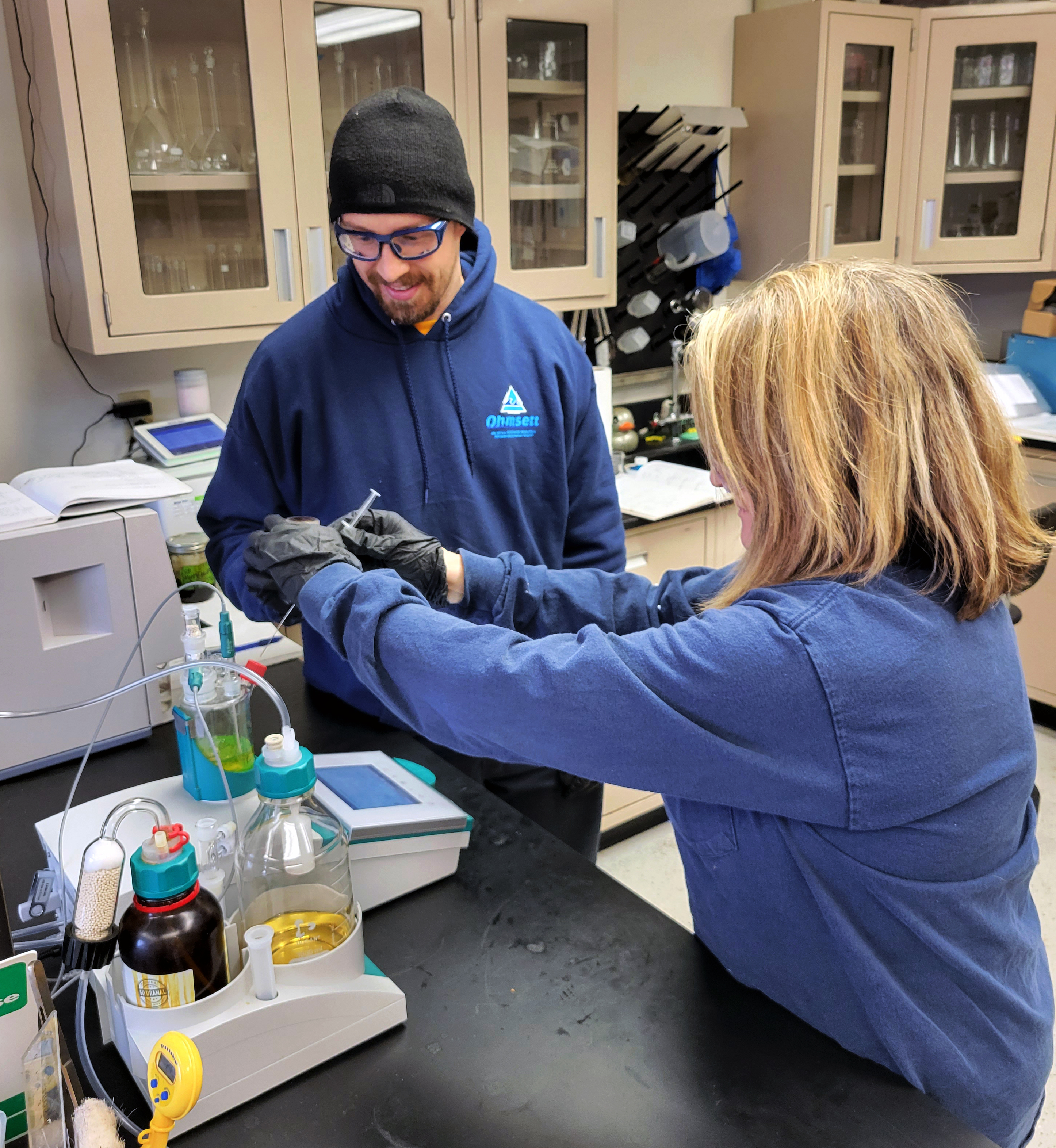

In the wave tank and laboratory environment, manufacturers can test the efficiency of new designs or quantify improvements to existing equipment against a wide range of controlled environmental conditions using oil with known characteristics and real-time data analysis. They can learn more about their products, allowing them to redesign and develop more effective technology and procedures for responding to future oil spills.

The facility also supports research projects to study oil behavior, pumping strategies, towing forces, oil/mineral aggregates, biofuels, remote sensors, submerged and sunken oil, and chemical dispersants, to name just a few.

Current researchers have included government agencies, universities, private companies, and environmental research organizations.